Bathroom waterproofing with the help of the Maxima Hidromax line

The bathroom is the part of the living space that is most exposed to moisture and water, which is why quality protection against harmful effects is necessary. Proper selection of materials and expertly executed works are of crucial importance for high-quality waterproofing of these spaces. In the case of poorly executed works or the use of bad materials, the removal of defects and damage is a long and expensive procedure. Maxima offers in its assortment waterproofing coatings ideal for bathroom waterproofing, which are easy to apply, waterproof and contain selected additives that improve water repellency and water resistance.

Today we bring you the characteristics of three Maxima products from Hidromax lines, Hidromax Flex, Hidromax Elastic te Hidromax Liquid Foil. Get to know the products from the Maxima Hidromax line and protect your bathroom from moisture.

HYDROMAX® Flex

HIDROMAX Flex is a flexible 2k mass made on the basis of cement enhanced with water-repellent and waterproof polymers, specially selected aggregates, refined with special additives. It consists of dry component A and liquid component B, which are mixed to form a pasty mass that is applied with a brush or metal trowel. It is used to protect concrete and buildings from the appearance of capillary moisture, water penetration into the floor

at low pressure and in situations where it is necessary to ensure watertightness in case of positive hydrostatic water pressure. It is recommended for waterproofing bathrooms, kitchens, buried walls, basement and basement rooms, foundation strips, tanks, terraces and balconies.

Method of use

The surface must be: load-bearing, clean and free of loosely bonded parts, dust, water-soluble salts, grease and other impurities. Concrete surfaces, cement screeds and mortar must be old min. 28 days. Fill large dents and damaged elements with KERAMOL glue or repair mortar. Gradually add the contents of one bag (component A) 12 kg to 5 kg of liquid (component B) with constant mixing, until a homogeneous mass suitable for application with a brush is obtained. The mass prepared in this way is ready for installation and must be used within 1 hour. Before applying waterproofing, the surface should be wet. Apply the prepared mass with a stiff and robust brush, in two coats, using a cross procedure. Apply the second coating immediately after the hardening of the first layer that has not completely dried. For surfaces that are exposed to a strong influence of water, the need for 3 or 4 applications is possible. If the time between applying two layers is longer than 24 hours, lightly sandblast the previous layer. The minimum thickness of an individual layer is 0.7mm, and the maximum is 2mm. Corners, drains and penetrations of pipes should be insulated using insulating strips. It is possible to walk on the insulated surface after 3 days. Ceramic tiles can be laid for 3 to 5 days depending on the thickness of the layer and climatic conditions.

HIDROMAX® Elastic

HIDROMAX Elastic is an elastic 2k mass made on the basis of cement and specially selected aggregates, enhanced with water-repellent, waterproof and alkali-resistant polymers, reinforced with fibers, refined with special additives for waterproofing and protection of concrete surfaces. It consists of dry component A and liquid component B, which are mixed to form a pasty mass that is applied with a brush or metal trowel.

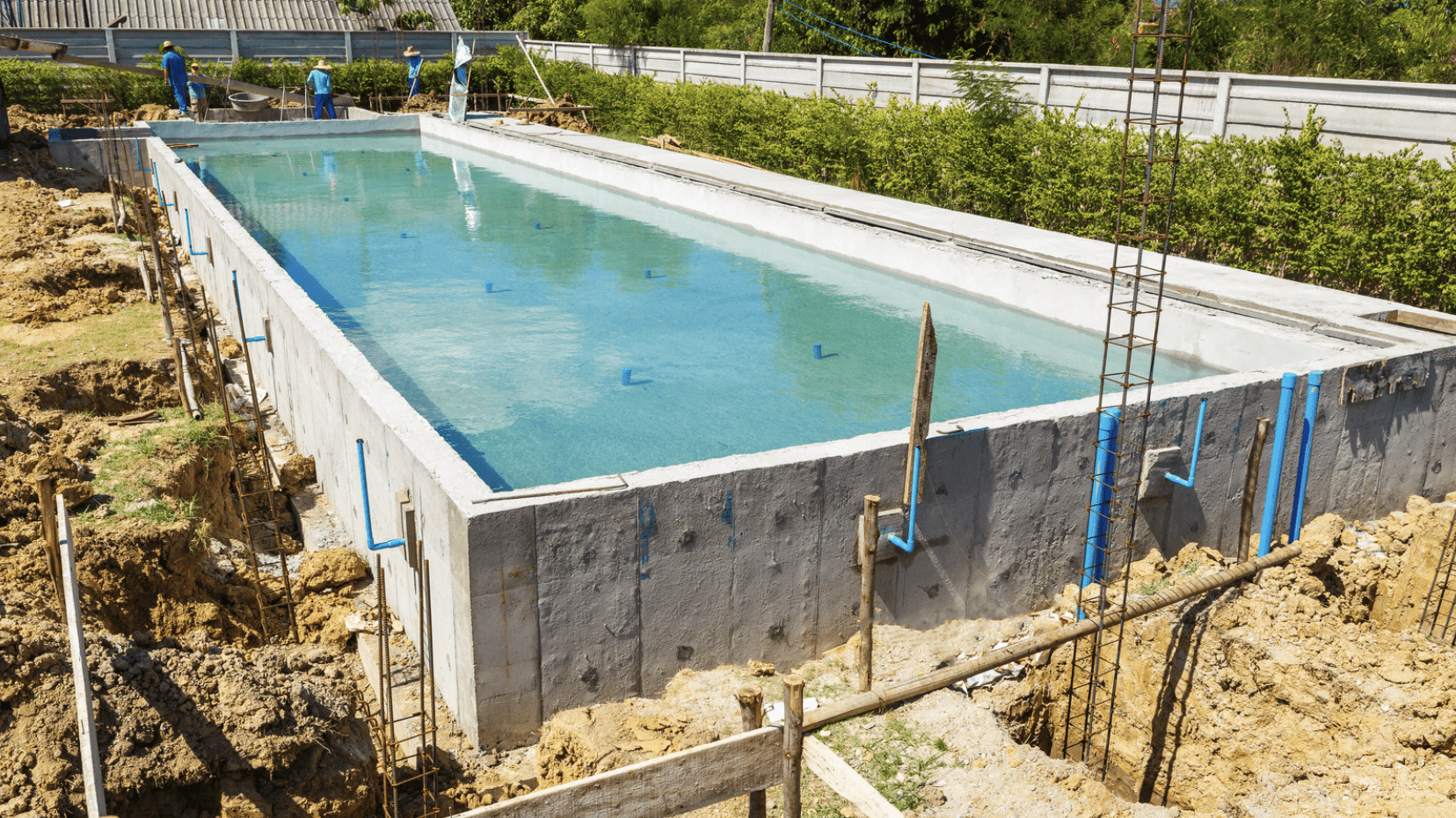

It has the ability to bridge cracks, adheres well to mineral surfaces, can be applied even at lower temperatures and in humid conditions. It is used to protect buildings from the appearance of capillary moisture, penetration of water under pressure, as well as in situations where it is necessary to ensure watertightness during positive and higher negative hydrostatic water pressure. It is recommended for the waterproofing of kitchens, bathrooms, buried walls, basement and basement rooms, foundation strips, swimming pools, terraces and balconies, i.e. all surfaces exposed to atmospheric influences and stresses due to bending.

Method of use

The surface must be: load-bearing, clean and free of loosely bonded parts, dust, water-soluble salts, grease and other impurities. Concrete surfaces, cement screeds and mortar must be old min. 28 days. Fill large dents and damaged elements with KERAMOL glue or repair mortar. Add the contents of one bag (component A) 10 kg gradually to 5 kg of the liquid part (component B) with constant mixing, until a homogeneous mass suitable for application with a brush is obtained. The mass prepared in this way is ready for installation and must be used within 1 hour. Before applying waterproofing, the surface should be wet. Apply the prepared mass with a stiff and robust brush, in two coats, using a cross procedure. Apply the second coating immediately after the hardening of the first layer that has not completely dried. For surfaces that are exposed to a strong influence of water, the need for 3 or 4 applications is possible. If the time between applying two layers is more than 24 hours, lightly sandblast the previous layer. The minimum thickness of an individual layer is 0.7mm, and the maximum is 2mm. Corners, drains and penetrations of pipes should be insulated using insulating strips. It is possible to walk on the insulated surface after 3 days. Ceramic tiles can be laid for 3 to 5 days depending on the thickness of the layer and climatic conditions.

HYDROMAX Liquid Foil is a 1k waterproofing coating, based on a dispersion of special polymer binders, carefully selected additives that improve water repellency and water resistance, and specially selected aggregate fillers. The coating forms a flexible, quick-drying waterproof membrane.

It is ready to use and easy to apply. It is intended for external and internal use on horizontal and vertical surfaces such as terraces, balconies and rooms that are exposed to the occasional influence of water: kitchens, bathrooms, shower cabins, public toilets, etc. It can also be used in systems with underfloor heating. It can be applied to: concrete, cement screeds, cement plasters, plasterboard (interiors only), ceramic tiles, terrazzo, stone, etc.

HIDROMAX Liquid Foil is not a final layer and a solid protection must be installed over it (ceramic tiles, stone, mosaic, concrete, etc.). The coating is not harmful to humans and the environment.

Method of use

The surface must be: load-bearing capacity, clean and free of weakly bonded parts, dust, water-soluble salts, grease and other impurities. Concrete surfaces, cement screeds and plaster must be at least 28 days old. Fill large dents and damaged elements with KERAMOL glue or repair plaster. On cement substrates with a moisture content of more than 3%, on substrates with capillary absorption of moisture, on gypsum plasters with a content of

moisture content higher than 1% and on gypsum leveling compounds with a moisture content higher than 0.5%, may not be applied. Smooth surfaces such as old tiles and terraces should be sanded and dust removed beforehand. HIDROMAX Liquid Foil is delivered ready for use. It should be mixed well and should not be diluted.

Apply the material with a stiff brush or long-haired roller, in two coats with a total thickness of min. 1.0mm and no larger than 1.5mm. Apply the second layer crosswise in relation to the first layer, after a minimum of 4 hours from the application of the first layer, i.e. when the first layer dries, darkens and obtains a matte surface. Corners, sinks and pipe penetrations should be insulated using HIDROMAX insulating tapes, which are pressed into the first layer and coated with the second. Further processing

treated surface, i.e. installation of solid covering (ceramic tiles, stone, mosaic, concrete, etc.) is possible after a minimum of 6 hours from the application of the second layer.

Protect your bathroom from moisture and make sure of the quality Maxima Hidromax products.

Sve Maxima you can find the products in our sales centers in Zagreb and soon in Split, and you can also visit us contact for all questions and advice.

Follow us on social networks as well Instagram, Facebook i LinkedIn and log in to our weekly newsletter so that you are always up to date with all the trends, tips and products for waterproofing.